DIY Rustic Hickory Countertops for the Van Conversion

Materials needed for this project —>

Rustic hickory planks

A brush for staining from a local hardware store

Water-based Polyurethane satin finish

A neighbor with woodworking tools (seriously, go find one)

I’m here for ya.

Seriously! Reach out on Instagram or YouTube with questions.

The video has cool time-lapses in it. Check it out.

Step 1:

Choose your wood!

I was originally going to purchase a super expensive “butchers block” piece from Home Depot. I talked to my neighbor about it and he was so offended I’d dare spend that much when all I really wanted was a dark, rustic, high-grain (chaotic-looking) look and had no attachment whatsoever to the expensive Home Depot product.

He suggested I try Rustic Hickory as it is wayyy cheaper per board foot (how you purchase lumber traditionally).

Step 2:

Try out some stains.

The harder a wood is the less stain will take to that wood. So, some experimentation was necessary to find the look I wanted with my wood.

You can buy different shade stains and you also can change the way you apply the stain to achieve different shades. Brush the stain on and wipe off immediately for a lighter shade. Brush it on and wait a minute before wiping it off (thereby allowing more stain to absorb into the wood) to get a darker shade.

Step 3:

Cut and glue your planks.

When you make your initial cuts for beginning the assembly of your countertops, it’s important to leave extra length and width than you will need for your final product in order to account for movement of the boards when you glue them up (they will shift a little when you clamp them up), as well as the need to sand and refine your edges as you get closer to the final product.

I left a good 2” extra in every direction where I could to make sure that I had plenty of room to work with as I progressed.

PRO TIP: when gluing planks together, make sure that the grain of each plank is opposite the one next to it. (The planks will have bowl-shaped grain patterns in the ends, flip every other board so that the bowls are facing up then down then up then down etc.) This is your best bet at avoiding major warping as this strategy ensures that each warp will pull against the warp next to it.

Spread wood glue along the edges of each board with your finger then clamp up using clamps both on top and below the planks to try to maintain a flat surface for your countertop.

Step 4:

Prep for sanding.

When the glue has dried (after 24 hours), take a tool and scrape off all the little glue blobs that squeezed out of your seams to protect the sander from catching and tearing.

You can do this after a few hours when the glue is rubbery or wait until it is fully dried and hardened. It is a matter of preference.

Step 5:

Sand and cut to length.

My neighbor had a massive sander for running large objects through in order to get a flat surface. The newly glued planks will each be sitting slightly differently than the planks on either side. This is a normal product of gluing up planks. In order to get a flat surface you need to sand the whole thing down to be level.

The machine my neighbor had made this easy. Doing it by hand (especially with hard wood like hickory) would take a long time and be very hard to come out with a perfect product (since your sanding will not be as even a machine’s).

If you cannot find a woodworking neighbor, maybe look for a local lumberyard or similar place that might have a machine you could ask to use.

After the top surface is level from sanding, I cut the countertops to their final lengths and widths.

Step 6:

Cut out holes for appliances.

I was making space for my chest fridge to be able to open through the top of one of the countertops as well as a hole for my sink to sit inside and a hole for my induction stove to sit inside.

These cuts were incredibly stressful since a mistake here would send me back to the beginning…

I jigsawed out the holes then sanded and routered the edges that would be visible. I also routered or sanded the top edges of my countertops that would be forward-facing (aka not against the wall).

Just go slowly and measure like 46 times to make sure you don’t make a mistake here.

Step 7:

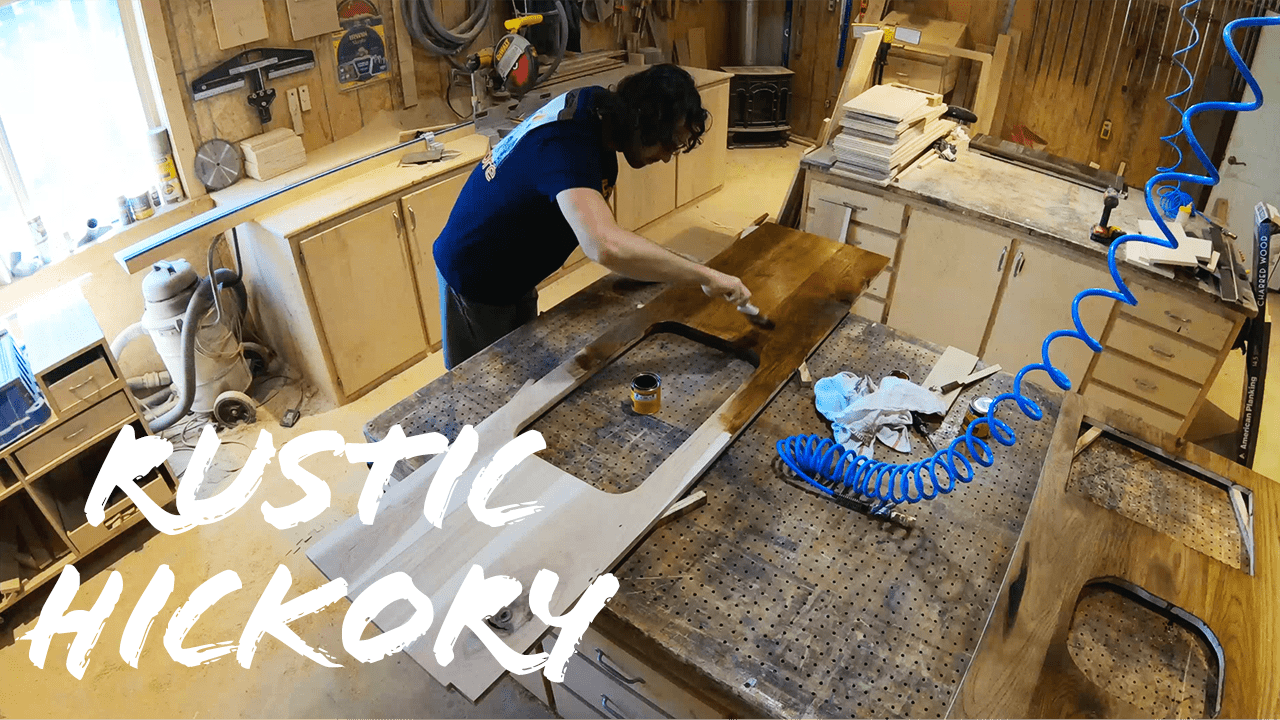

Stain and coat with poly!

This is the easy and exciting part. After you’ve made sure you’ve made your last cuts and sanding adjustments on your countertops, it’s time to stain!

As I mentioned before, the shade you want in your wood relies a lot on how you go about applying (wiping off with a rag right away or waiting a bit). So, be mindful of that as you begin staining.

I used a standard staining brush from my hardware store, some Provincial oil-based stain and a rag.

I brushed on the stain on the top and edges and then wiped off using that rag with no rush at all since I wanted to leave the stain to soak into the wood as long as possible given my desire for a dark finish as well as the hardness of hickory.

I used water-based polyurethane to put 4 coats on top of that stain once the stain had 24 hours to dry. Each coat of poly needs at least 2 hours (depending on what you’re using, read the back) to dry before sanding lightly to prep for the next coat.

My neighbor had a sprayer we used for the poly but I believe you can brush it on as well.

Step 8:

Attach by screwing into the bottom of the countertop.

Once everything was dried, I took the countertops out to the van, set them in place, had my friend sit on them to weigh them down, then used 2” decking screws to drill through the 2x4 supports in my kitchen and desk area into the bottom of the countertop.

Make sure you measure your support thickness (in my case, about 1.5” since a 2x4 is not actually 2x4 inches ha!) and the thickness of your countertop (in my case, about 3/4” thick). Then drill carefully so you don’t accidentally countersink your screw deeply and screw right through the top of your beautiful countertop :(

Final thoughts:

If you can find a neighbor with woodworking tools, build your own countertops!

It is so rewarding knowing 1) I saved a ton of money by building these myself and 2) that they were created with my own two hands and therefore mean infinitely more to me than a pre-made option from Home Depot ever could.